Tools for precision machining stands at the core of the modern manufacturing process, shaping the very foundation of the products we use daily.

This high-precision field involves removing raw materials to a desired size with a fine level of accuracy, employing a variety of sophisticated tools and techniques. From aerospace components to medical devices, tools for precision machining ensure the functionality and reliability of finished products.

Table of Contents

In the following sections, we will delve into the key tools for precision machining including more about laser cutting materials – exploring their functions, benefits, and the innovation they bring to the manufacturing floor.

CNC Machines

One of the most important tools for precision machining are CNC machines. CNC (Computer Numerical Control) machines represent a monumental leap in manufacturing technology, transforming the way components are fabricated.

These sophisticated machines use computer programming to automate the control of machining tools like drills, lathes, and mills. This allows for the creation of complex parts with a high degree of precision and repeatability, which is essential in industries where consistency and quality are paramount.

The use of CNC machines brings numerous benefits, including increased production speed, reduced human error, and the ability to produce complex geometries that would be nearly impossible to achieve manually.

Additionally, CNC machines are highly adaptable to various materials and design changes, making them indispensable for custom manufacturing and rapid prototyping.

Not to mention, the ability to monitor and analyze data from CNC machines provides crucial information for process improvement and quality control efforts. With continuous advancements in technology, CNC machines continue to play a vital role in the precision machining industry.

Gearing Systems

Gearing systems are critical components in the manufacturing industry, acting as conduits for power transmission in machinery.

These tools for precision machining consist of gears that mesh together to transmit torque and alter the speed between electric motors and machinery devices. The precise design of gears ensures efficient performance and is crucial for machines that require specific torque or speed ratios.

In manufacturing, gearing systems find usage in various applications such as conveyor belts, automotive transmissions, and robotics. They are particularly vital in areas where precise movement control is necessary, for instance, in automated assembly lines or when manipulating the orientation of components during fabrication.

The durability and reliability of gearing systems influence the overall efficiency and productivity of manufacturing operations, making their design and maintenance paramount for successful industrial outcomes.

The key components of gearing systems are gears, racks, shafts, and bearings. Each component has specific design considerations that affect gear performance and reliability. With advancements in material science and computer-aided design, manufacturers can now produce gears with greater precision and durability.

From a rack and pinion gear system to a worm gear set, the versatility of gearing systems makes them essential for precision machining in various industries.

Plus, the integration of computerized controls has resulted in more accurate and efficient gear production, further enhancing their role in precision manufacturing.

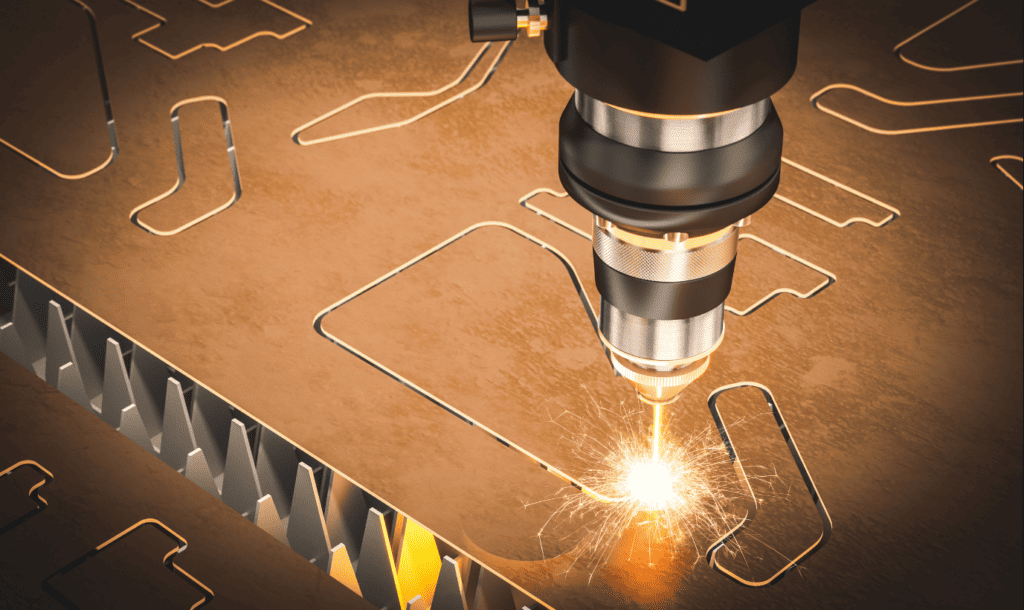

Laser Cutting Devices

Laser-cutting technology has revolutionized precision machining, providing highly accurate and efficient methods for material removal. By using a high-powered laser beam, these devices can quickly cut through a variety of materials with exceptional precision, making them invaluable in the production of intricate parts and components.

The use of lasers also eliminates the need for physical contact between tools and workpieces, reducing wear and tear and increasing the lifespan of tools.

The application of laser cutting extends beyond traditional machining methods, with uses in the medical, aerospace, and jewelry industries. The non-contact nature of laser cutting also reduces material distortion, making it ideal for thin materials like sheet metal or delicate components.

Furthermore, computerized controls allow for precise positioning and movement control, resulting in highly detailed cuts and intricate shapes that were previously unattainable.

In addition to cutting, lasers can also be used for engraving, welding, and surface treatment, providing a versatile tool for a wide range of precision machining processes. With continuous advancements in laser technology, the possibilities for precision manufacturing are endless.

3D Printers

3D printing is a rapidly expanding field in precision machining, allowing for the creation of complex three-dimensional objects from digital designs. By laying down layer upon layer of material, 3D printers can produce highly accurate and detailed models with a high level of repeatability.

This technology has revolutionized prototyping and small-batch production, providing a cost-effective and efficient alternative to traditional manufacturing methods.

3D printers excel in creating intricate geometries and designs that would be impossible to achieve with traditional machining techniques. Plus, the use of additive manufacturing reduces material waste and allows for greater design flexibility, making it ideal for custom or one-off parts.

Additionally, 3D printing has enabled the production of complex structures with internal channels and voids, further expanding its potential uses in precision machining.

As with other tools for precision machining, the continuous advancements in 3D printing technology have resulted in improved accuracy, speed, and material options. From plastic to metal and even living tissue, the possibilities for this versatile tool are endless.

Lathes and Mills

Lathes and mills are traditional machining instruments that have evolved over time to become highly accurate and efficient tools for precision manufacturing.

Lathes rotate a workpiece while a cutting tool shapes it into the desired form, while mills use rotating cutters to remove material from a stationary workpiece. These machines can produce precise cuts with incredible speed, making them essential for high-volume production.

Lathes and mills find extensive usage in the production of cylindrical components, such as screws, bolts, and shafts. With computerized controls, these machines can achieve micron-level precision, resulting in parts with tight tolerances and smooth finishes.

The versatility of lathes and mills also allows for a wide range of materials to be used, making them suitable for various industries, from automotive to aerospace.

As technology continues to advance, lathes and mills are becoming increasingly automated, further enhancing their accuracy and efficiency.

The integration of sensors and real-time monitoring allows for quick detection of errors or malfunctions, reducing downtime and increasing overall productivity. As a result, these traditional machining tools remain vital to the precision manufacturing process.

Milling Machines

Milling machines are dynamic tools for precision machining, essential for shaping solid materials like metal, wood, and plastics. Through a process of cutting and drilling, these versatile tools can perform a multitude of functions such as slotting, threading, and rounding of parts.

Typically, a milling machine uses a rotary cutting tool that moves along multiple axes, capable of creating a variety of shapes, slots, holes, and details in a workpiece.

The manufacturing industry benefits greatly from the use of milling machines, as they are suitable for producing everything from small, precise parts used in watches and electronics to large, rugged components found in construction and aerospace.

Their ability to machine complex contours and features precisely means that milling machines are invaluable for creating prototypes and end-use production parts with high accuracy.

Furthermore, milling machines are continually evolving with technological innovations. The introduction of CNC technology has revolutionized milling, allowing for automated, highly accurate, and repeatable machining processes.

As a result, industries can benefit from reduced production times, decreased manual labor, and minimized errors, enhancing overall efficiency and productivity on the manufacturing floor.

Precision Grinding Tools

For any process requiring an extremely smooth surface finish or tight tolerances, grinding tools for precision machining are the answer.

They remove small amounts of material through a grinding wheel and can achieve the best possible surface precision, essential for many high-precision parts in various industries. From gears to turbines, precision grinding is a necessary step in the manufacturing process.

Precision grinding tools use different abrasive materials, such as diamond or aluminum oxide, depending on the material being machined and the desired finish.

They can also operate at high speeds and with varying degrees of pressure, resulting in smooth surfaces that require minimal post-processing. The introduction of CNC controls has further enhanced the precision and accuracy of grinding, making it a crucial tool for achieving tight dimensional tolerances.

Innovations in grinding technology have also led to the development of new methods such as creep feed grinding and centerless grinding, providing even greater precision and efficiency.

With advancements in materials and cutting-edge techniques, grinding tools for precision machining will continue to play a critical role in the manufacturing process.

Measuring Instruments

The unsung heroes of tools for precision machining are the measuring instruments. Quality control is paramount, and tools like calipers, micrometers, and coordinate measuring machines (CMMs) ensure that each part meets stringent specifications. Accurate measurements are crucial for maintaining the tolerances required in high-precision industries.

Measuring instruments also play a significant role in process improvement, as they provide data for statistical process control and help identify areas for optimization. The integration of computerized systems allows for automated inspection processes, further enhancing productivity and accuracy.

In conclusion, precision machining is an integral part of modern manufacturing, influencing the quality, efficacy, and innovation of products across numerous industries.

Through the synergy of CNC machines, gearing systems, laser cutting devices, 3D printers, lathes, mills, milling machines, precision grinding tools, and meticulous measuring instruments, manufacturing has achieved levels of accuracy and efficiency previously deemed unattainable.

This technological evolution continues to propel the manufacturing industry forward, promising a future where the only limitation is the breadth of human creativity.

As we continue to develop and refine these tools for precision machining, we solidify the foundation of an industry that not only prides itself on the precision of its products but also in its unwavering pursuit of perfection.

Tools for Precision Machining – FAQs

Q1: What are the predominant advantages of using CNC machines in precision machining?

A1: CNC machines offer unparalleled advantages in precision machining, including heightened production speed, consistency, and accuracy.

They reduce human error and can produce complex geometries that are nearly impossible to achieve manually. Their adaptability allows for easy reconfiguration to suit different materials and designs, making them invaluable for custom manufacturing and rapid prototyping.

Q2: How do gearing systems enhance manufacturing operations?

A2: Gearing systems are crucial for the efficient transfer of power within machinery.

They enable precise control of torque and speed, which is vital for machinery that must operate at specific ratios. Reliable and accurately designed gearing systems are foundational to the performance and productivity of manufacturing operations.

Q3: In what ways has laser-cutting technology impacted material processing?

A3: Laser-cutting technology has significantly impacted material processing by enabling precise cuts without physical contact, which minimizes tool wear and material distortion.

Its ability to produce intricate parts and components swiftly and cleanly has found applications in various industries, including medical, aerospace, and jewelry making.

Q4: What are the unique capabilities of 3D printers in the manufacturing process?

A4: 3D printers have unique capabilities in manufacturing, particularly in creating complex shapes that traditional machining cannot achieve.

They excel in rapid prototyping, custom part production, and constructing designs with intricate geometries and internal structures. The continuous advancements in 3D printing technologies have expanded material options and improved precision.

Q5: Why are measuring instruments considered integral tools for precision machining?

A5: Measuring instruments are integral tools for precision machining because they provide the precise measurement data necessary for quality control, ensuring that parts meet exacting specifications.

They are also essential for process improvement by offering insights that help refine manufacturing operations. Technological integration allows for automated, accurate, and efficient inspection processes.