Investing in an industrial dehumidifier for your business can be a game changer, especially if you are in industries such as food production, pharmaceuticals, or storage.

Table of Contents

However, before you rush into purchasing this equipment that promises to regulate humidity levels and protect your goods from moisture-related damages, there are several factors that need careful consideration.

After all, it is not just about buying the most expensive or the latest model on the market – you need to choose the one that suits your specific needs and budget.

In this article, we will discuss some key points to keep in mind before investing in an industrial dehumidifier for your business and how it can benefit your operations. Let's get started!

Understand Your Needs

The first step in choosing the right industrial dehumidifier is understanding the specific needs of your business environment.

Factors such as the size of the space that needs dehumidifying, the average humidity levels in your geographical area, and the particular requirements of the goods or materials stored are all crucial in making an informed decision.

Industries dealing with perishable goods might need a more powerful dehumidifier to maintain optimal conditions and prevent mold growth, whereas businesses storing electronics might require precise humidity control to prevent corrosion.

Based on your specific needs, you can determine the type, size, and capacity of the dehumidifier that will be most effective for your business.

Buying vs. Rentals

Before making a significant investment in an industrial dehumidifier, here are some questions you should ask yourself: How long will I need this equipment? Will my needs change in the future? If your business is seasonal, do you need a dehumidifier all year round?

Considering these questions can determine whether it makes more sense to purchase or rent an industrial dehumidifier. Even though buying may seem like a more cost-effective option in the long run, it also comes with added responsibilities such as maintenance and repairs.

On the other hand, renting provides flexibility and convenience, especially for businesses that only require dehumidifiers during certain times of the year. Certain rental suppliers like constructionheatersinc.com even offer customized rental plans for businesses with unique needs rather than a one-size-fits-all solution that comes with a purchase.

The potential downsides of renting, however, include not having full control over the equipment and higher long-term costs. Regardless of whether you choose to buy or rent an industrial dehumidifier, it is essential to carefully consider all the pros and cons before jumping into a decision.

Types of Industrial Dehumidifiers

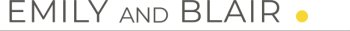

Industrial dehumidifiers come in various types, and each has its distinct capabilities and limitations. Some of the common types include refrigerant, desiccant, and ventilating dehumidifiers. Let's take a closer look at each.

Refrigerant Dehumidifiers

Widely used in various industries, refrigerant dehumidifiers operate by drawing moist air across cold coils, condensing the moisture, which is then collected in a container or drained away. This type is particularly effective in environments with relatively high temperatures and humidity levels, making them ideal for use in settings such as food processing plants or warehouses storing sensitive materials.

Note that their efficiency can decrease significantly in cooler conditions, where the dew point is low. The result is that some refrigerant dehumidifiers might not be able to remove enough moisture from the air, leading to ineffective dehumidification.

Desiccant Dehumidifiers

Unlike refrigerant dehumidifiers, desiccant models use a chemical substance called a desiccant to absorb moisture from the air.

This type of industrial dehumidifier is suitable for use in colder environments as they are more effective at removing moisture from the air, regardless of the temperature. However, desiccant dehumidifiers also require a heat source to operate, which can add to their operational costs.

Ventilating Dehumidifiers

As the name suggests, ventilating dehumidifiers work by exchanging moist indoor air with drier outdoor air, resulting in a lower overall humidity level.

This type of dehumidifier is ideal for use in areas with high heat and humidity levels and can be highly energy-efficient. However, they are not as effective in colder environments and may require additional insulation to prevent heat loss.

Consider the Installation Process

The installation process for an industrial dehumidifier can vary depending on the type and model you choose. For instance, refrigerant dehumidifiers often require ductwork to be installed while desiccant or ventilating models may need additional wiring or plumbing work.

Whether you decide to buy or rent, it is crucial to factor in the installation process and its associated costs before taking the leap.

If you are renting, make sure to discuss the installation with a supplier to ensure a smooth and hassle-free process. The last thing you want is unexpected costs or delays in your operations due to an improperly installed dehumidifier.

Energy Efficiency

The energy efficiency of a dehumidifier directly influences operational costs. Energy-efficient models, while potentially more expensive upfront, can lead to significant cost savings over time by reducing electricity consumption.

Look for dehumidifiers with Energy Star ratings or those that incorporate advanced technologies designed to minimize power usage without compromising performance.

Even consider the overall climate and specific environmental conditions of your operation’s location, as these factors can significantly impact the efficiency and effectiveness of your chosen dehumidifier. Investing in an energy-efficient model is sure to pay off in the long run, especially if your business runs round-the-clock operations.

Cost

The cost of an industrial dehumidifier can range from a few hundred dollars to tens of thousands, depending on the type, size, and features. As mentioned earlier, purchasing may seem like a more cost-effective option in the long run, but it also comes with additional expenses such as maintenance and repairs.

Besides considering the initial purchase or rental costs, know the operational costs associated with running and maintaining your chosen dehumidifier. These can include electricity, water usage, filter replacements, and more. Don't forget to factor in the estimated lifespan of the equipment and potential costs for replacement parts or upgrades.

Noise Levels

Industrial dehumidifiers are not known to be the quietest of equipment, but some models are noisier than others. If you are planning on using the dehumidifier in a noise-sensitive environment such as an office or laboratory, the best course of action would be to choose a quieter model over one that offers higher capacity or performance.

Similarly, if the dehumidifier will be placed in an area where employees or customers frequent, consider investing in noise-reducing accessories or models with sound-dampening features.

Maintenance and Upkeep

Like any other industrial equipment, you should never skip on maintaining your dehumidifier. Ensure you have a regular maintenance schedule in place and factor in the associated costs when budgeting for your investment. Here are some basic maintenance tasks to keep in mind:

Filter Replacement

Most industrial dehumidifiers require filter replacements at least once a year. Yet, this can vary depending on how frequently the equipment is used and the type of environment it operates in. Neglecting to replace dirty or clogged filters can lead to poor performance, increased energy consumption, and potential damage to the equipment.

Condenser Coil Cleaning

The coils in a dehumidifier work similarly to those in an air conditioner so they can also collect dirt and debris over time. Regular cleaning of the condenser coils can maintain optimal performance and prevent potential breakdowns.

Drain Line Maintenance

In refrigerant dehumidifiers, the moisture collected is drained out through a line away from the equipment. Make sure the drain line is free of any blockages and properly installed to avoid leaks or other issues.

Warranty and Support

Industrial dehumidifiers, like any other equipment, can experience malfunctions or breakdowns. Before making a purchase, inquire about the warranty and after-sales support provided by the manufacturer or supplier. A reliable warranty can save you significant costs in case of unexpected issues with your dehumidifier.

The same goes for rental equipment — you must ask reliable suppliers if they offer warranties and 24/7 support for their rental equipment, ensuring that your business operations continue smoothly without any interruptions. In any case, always have a contingency plan in case of emergencies or unforeseen circumstances.

Investing in an industrial dehumidifier is not a decision to be taken lightly as it requires a comprehensive understanding of your business's specific needs, the various options available, and the long-term implications of your choice.

Whether you decide to buy or rent, focus on selecting a unit that not only addresses your immediate requirements but also aligns with your operational budget, energy efficiency goals, and maintenance capabilities.

The right dehumidifier can significantly improve the quality of your workspace, safeguard your products, and most importantly, contribute to the overall success of your operations. Take the time to research, consult with experts, and carefully weigh your options to ensure that your investment yields favorable outcomes for years to come.

Industrial Dehumidifier FAQs

What is the optimal humidity level for an industrial environment?

The optimal humidity level for industrial environments typically ranges between 40% to 60%. This range prevents the growth of mold and bacteria, ensures the integrity of goods and machinery, and provides a comfortable atmosphere for workers.

However, specific industries may require different humidity levels based on the nature of their operations and the materials they handle so it is essential to consult with experts before determining the ideal humidity level for your business.

Can an industrial dehumidifier prevent mold growth?

Yes, an industrial dehumidifier can prevent mold growth by maintaining optimal humidity levels. Mold thrives in moist environments, and reducing the moisture content through dehumidification can inhibit its growth.

How often should I replace the filters on my dehumidifier?

Filter replacement frequency can vary depending on usage and environment, but it's recommended to replace them at least once a year. Check the manufacturer's instructions for specific recommendations for your dehumidifier model. Regularly clean or replace filters if they become visibly dirty or clogged.

Is it necessary to hire a professional to install an industrial dehumidifier?

The installation process can vary depending on the type of dehumidifier and your business's unique needs. In some cases, it may be necessary to hire a professional to ensure proper installation and avoid potential issues. Consult with the manufacturer or supplier for specific instructions and recommendations for your chosen unit.